Sehemu za Gia za Sayari za BABR Precision

Kuegemea

● Mipangilio ya gia ond iliyopitishwa kwa uwiano wa ushiriki mara mbili ya gia za kawaida za spur, huangazia hali ya kukimbia laini ya kelele ya chini, torati ya juu na kibali cha chini cha nyuma.

● Gia zimetengenezwa kwa chuma cha aloi chenye ubora wa hali ya juu, kikiwekwa kwa matibabu ya ugumu wa uso, kusagwa kwa kusaga kwa usahihi wa hali ya juu, na kutoa sifa nzuri ya kustahimili uchakavu na ukinzani wa athari.

| Mfano NO | Jukwaa | Uwiano | BABR042 | BABR060 | BABR090 | BABR115 | BABR142 | BABR180 | BABR220 | ||||||

| (Mominal Output Torque Tzn) | Nm | 1 | 3 | 9 | 36 | 90 | 195 | 342 | 588 | 1,140 | |||||

| 4 | 12 | 48 | 120 | 260 | 520 | 1,040 | 1,680 | ||||||||

| 5 | 15 | 60 | 260 | 325 | 650 | 1.200 | 2,000 | ||||||||

| 6 | 18 | 55 | 325 | 310 | 600 | 1,100 | 1,900 | ||||||||

| 7 | 19 | 50 | 310 | 300 | 550 | 1,100 | 1,800 | ||||||||

| 8 | 17 | 45 | 120 | 260 | 500 | 1,000 | 1,600 | ||||||||

| 9 | 14 | 40 | 100 | 230 | 450 | 900 | 1,500 | ||||||||

| 10 | 14 | 60 | 150 | 325 | 90 | 1.200 | 2,000 | ||||||||

| 14 | - | 42 | 140 | 300 | 50 | 1,100 | 1,800 | ||||||||

| 20 | - | 40 | 100 | 230 | 450 | 900 | 1,500 | ||||||||

| 2 | 15 | 14 | - | - | - | - | - | - | |||||||

| 20 | 14 | - | - | - | - | - | - | ||||||||

| 25 | 15 | 60 | 150 | 325 | 650 | 1,200 | 2,000 | ||||||||

| 30 | 20 | 55 | 150 | 310 | 600 | 1,100 | 1,900 | ||||||||

| 35 | 19 | 50 | 140 | 300 | 550 | 1.100 | 1,800 | ||||||||

| 40 | 17 | 45 | 120 | 260 | 500 | 1,000 | 1,600 | ||||||||

| 45 | 14 | 40 | 100 | 230 | 450 | 900 | 1,500 | ||||||||

| 50 | 14 | 60 | 100 | 230 | 650 | 1,200 | 2,000 | ||||||||

| 60 | 20 | 55 | 150 | 310 | 600 | 1,100 | 1,900 | ||||||||

| 70 | 19 | 50 | 140 | 300 | 550 | 1.100 | 1,800 | ||||||||

| 80 | 17 | 45 | 120 | 260 | 500 | 1,000 | 1,600 | ||||||||

| 90 | 14 | 40 | 100 | 230 | 450 | 900 | 1,500 | ||||||||

| 100 | 14 | 40 | 150 | 325 | 650 | 1,200 | 2,000 | ||||||||

| 120 | - | - | 150 | 325 | 650 | 1,100 | 1,900 | ||||||||

| 140 | - | - | 140 | 300 | 550 | 1,100 | 1,800 | ||||||||

| 160 | - | - | 120 | 260 | 550 | 1,000 | 1,600 | ||||||||

| 180 | - | - | 100 | 230 | 450 | 900 | 1,500 | ||||||||

| 200 | - | - | 100 | 230 | 450 | 900 | 1,500 | ||||||||

| (Torque ya Kusimamisha Dharura Tznor) | Nm | 1,2 | 3-200 | (Saa 3 za Torque ya Mominal) | |||||||||||

| (Kasi ya Jina ya Kuingiza N1N) | rpm | 1,2 | 3-200 | 5,000 | 5,000 | 4, 000 | 4, 000 | 3, 000 | 3, 000 | 2, 000 | |||||

| (Kasi ya Jina ya Kuingiza N1B) | rpm | 1,2 | 3-200 | 10,000 | 10,000 | 8, 000 | 8, 000 | 6, 000 | 6, 000 | 4, 000 | |||||

| (Micro Backiash PO) | arcmin | 1 | 3 ~ 20 | - | - | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | |||||

| 2 | 12-200 | - | - | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | |||||||

| (Kupungua kwa Msukosuko P1) | arcmin | 1 | 3 ~ 20 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | |||||

| 2 | 2 ~ 200 | ≤7 | <7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | |||||||

| (Msukosuko wa Kawaida wa P2) | arcmin | 1 | U | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | |||||

| 2 | 2 ~ 200 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | |||||||

| Ugumu wa torsion | Nm/arcnmin | 1,2 | 3 ~ 20 | 3 | 7 | 14 | 25 | 50 | 145 | 225 | |||||

| (Wakati wa juu zaidi wa kuinama M2kB) | Nm | 1,2 | 3-200 | 780 | 1,530 | 3, 250 | 6, 700 | 9, 400 | 14, 500 | 50, 000 | |||||

| (Nguvu ya radi inayoruhusiwa F2aB) | N | 1,2 | 3-200 | 390 | 765 | 1, 625 | 3, 350 | 4, 700 | 7, 250 | 25, 000 | |||||

| (Maisha ya huduma) | hr | 1,2 | 3-200 | 20,000 | |||||||||||

| (Ufanisi) | % | 1 | 3 ~ 20 | ≤95% | |||||||||||

| 2 | 12-200 | ≤92% | |||||||||||||

| (Uzito) | kg | 1 | 3 ~ 20 | 0.9 | 2.1 | 6.4 | 13 | 24.5 | 51 | 83 | |||||

| 2 | 2 ~ 200 | 1.2 | 1.5 | 7.8 | 14.2 | 27.5 | 54 | 95 | |||||||

| (Kipindi cha Uendeshaji) | ℃ | 1,2 | 3-200 | 0°C+90°℃ | |||||||||||

| (Kulainisha) | 1,2 | 3-200 | Mafuta ya lubrication ya syntetisk | ||||||||||||

| (Shahada ya ulinzi wa Gearbox) | 1,2 | 3-200 | |P65 | ||||||||||||

| (Nafasi ya Kupanda) | 1,2 | 3-200 | Maelekezo yote | ||||||||||||

| Kelele(n1=3000 rpmi=10, Hakuna mzigo) | dB(A) | 1,2 | 3-200 | ≤61 | ≤63 | ≤65 | ≤68 | ≤70 | ≤72 | ≤74 | |||||

Maelezo ya Bidhaa

PINTunatanguliza bidhaa zetu mpya, mfululizo wa kipunguzaji. Masafa yanapatikana katika aina mbalimbali za vipimo, vinavyowaruhusu wateja kuchagua bidhaa inayokidhi mahitaji yao vyema. Mfululizo wa kupunguza ni pamoja na vipimo 7: 042, 060, 090, 115, 142, 180 na 220, kutoa chaguzi kwa programu mbalimbali.

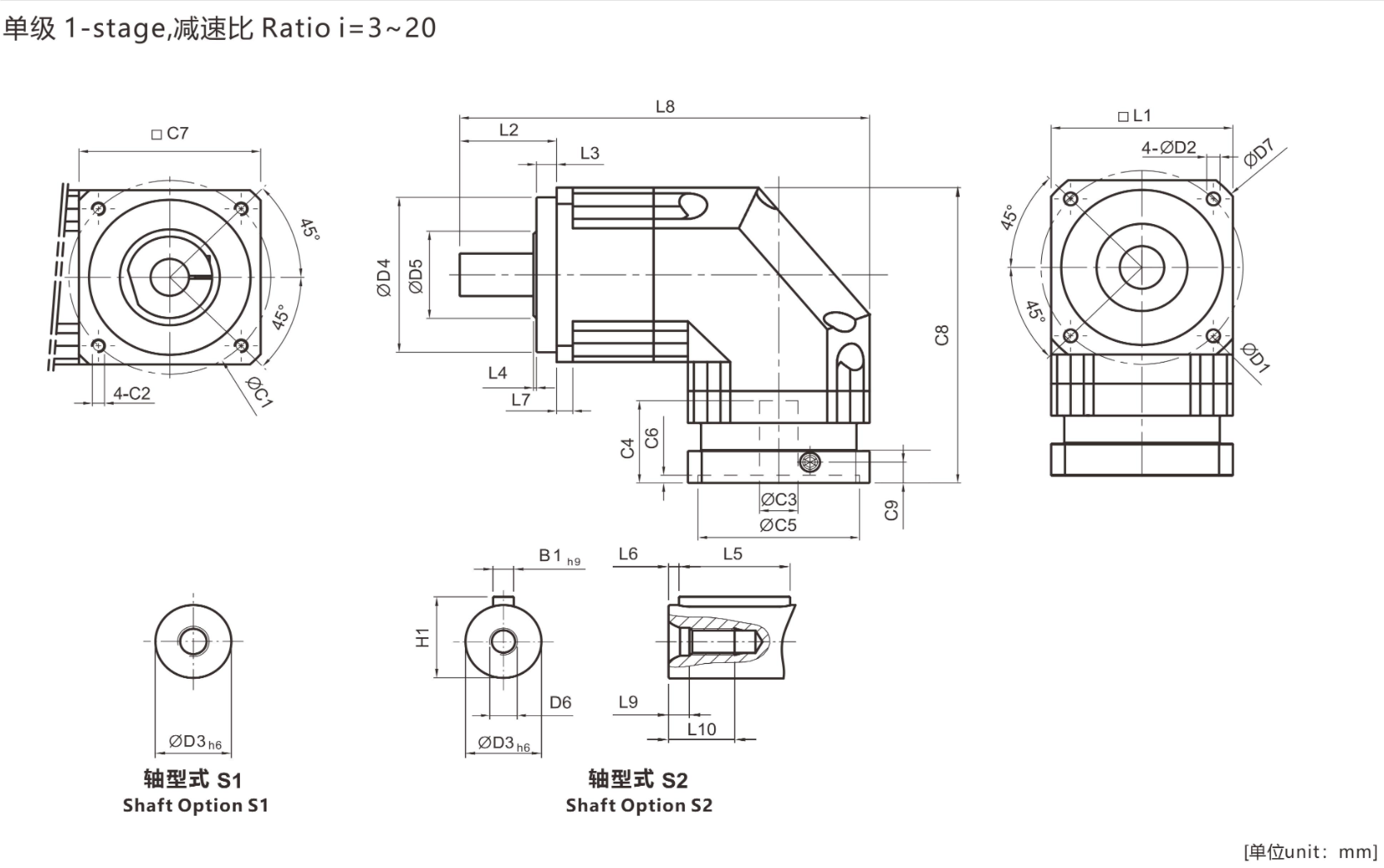

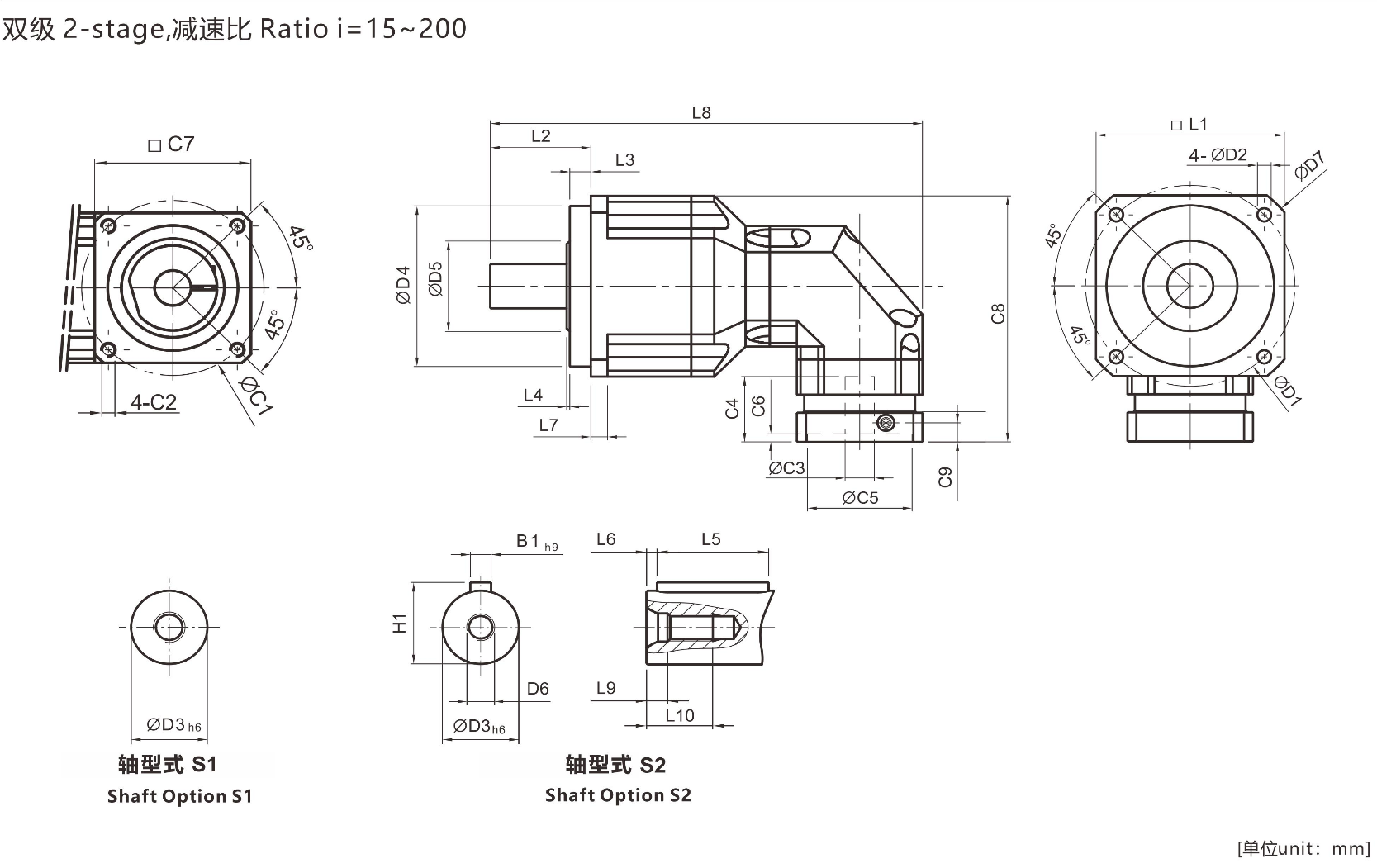

Msururu wetu wa kipunguzaji una torati ya kiwango cha juu iliyokadiriwa ya 2000Nm na inatoa utendaji bora. Kiwango cha uwiano wa kupunguza hatua moja ni kutoka 3 hadi 20, kuhakikisha udhibiti sahihi na uendeshaji bora. Kwa matumizi mengi zaidi, pia tunatoa hatua mbili zenye uwiano wa kupunguza kuanzia 15 hadi 200.

Moja ya sifa kuu za safu yetu ya kupunguza ni kuegemea kwake. Kupitisha muundo uliojumuishwa wa usaidizi maradufu ili kuongeza uthabiti na uwezo wa torque. Pembe ya pato ya 90° huruhusu usakinishaji unaonyumbulika katika nafasi zilizobana huku ukitoa chaguo mbalimbali za upitishaji.

Kudumu ni muhimu sana kwetu, ndiyo sababu gia katika safu yetu ya kupunguza hutengenezwa kutoka kwa nyenzo za aloi za hali ya juu. Gia hizi zimeimarishwa na kutengenezwa kwa mashine kwa kutumia mashine za kusagia gia zenye usahihi wa hali ya juu, na kuzipa upinzani bora wa kuvaa, upinzani wa athari na uimara.

Iwe unahitaji udhibiti madhubuti, utendakazi bora au utendakazi unaotegemewa, vipunguzi vyetu vingi vinaweza kukidhi mahitaji yako. Amini utaalam wetu na uchague anuwai yetu ya vipunguzi kwa mradi wako unaofuata. Jifunze tofauti katika utendaji na uaminifu wa bidhaa zetu.

Maombi

1. Uwanja wa anga

2. Sekta ya matibabu

3. Roboti za viwandani, Uendeshaji wa Viwanda, Sekta ya utengenezaji wa zana za mashine za CNC tasnia ya magari, uchapishaji, kilimo, tasnia ya chakula, uhandisi wa ulinzi wa mazingira, tasnia ya vifaa vya ghala.

| Dimension | BABR042 | BABR060 | BABR090 | BABR115 | BABR142 | BABR180 | BABR220 |

| D1 | 50 | 70 | 100 | 130 | 165 | 215 | 250 |

| D2 | 3.4 | 5.5 | 6.6 | 9 | 11 | 13 | 17 |

| D3 h6 | 13 | 16 | 22 | 32 | 40 | 55 | 75 |

| D4 g6 | 35 | 50 | 80 | 110 | 130 | 160 | 180 |

| D5 | 22 | 45 | 65 | 95 | 75 | 95 | 115 |

| D6 | M4x0.7P | M5x0.8P | M8x1.25P | M12x1.75P | M16x2P | M20x2.5P | M20x2.5P |

| D7 | 56 | 80 | 116 | 152 | 185 | 240 | 292 |

| L1 | 42 | 60 | 90 | 115 | 142 | 180 | 220 |

| L2 | 26 | 37 | 48 | 65 | 97 | 105 | 138 |

| L3 | 5.5 | 7 | 10 | 12 | 15 | 20 | 30 |

| L4 | 1 | 1.5 | 1.5 | 2 | 3 | 3 | 3 |

| L5 | 16 | 25 | 32 | 40 | 63 | 70 | 90 |

| L6 | 2 | 2 | 3 | 5 | 5 | 6 | 7 |

| L7 | 4 | 6 | 8 | 10 | 12 | 15 | 20 |

| L8 | 111.5 | 145 | 203 | 259 | 333 | 394 | 484 |

| L9 | 4.5 | 4.8 | 7.2 | 10 | 12 | 15 | 15 |

| L10 | 10 | 12.5 | 19 | 28 | 36 | 42 | 42 |

| C11 | 46 | 70 | 100 | 130 | 165 | 215 | 235 |

| C2¹ | M4x0.7Px10 | M5x0.8Px12 | M6x1Px12 | M8x1.25Px25 | M10x1.5Px25 | M12x1.75Px28 | M12x1.75Px28 |

| C3¹G7 | ≤11/≤12 | ≤14/≤16 | ≤19/≤24 | ≤32 | ≤38 | ≤48 | ≤55 |

| C41 | 25 | 34 | 40 | 50 | 60 | 85 | 116 |

| C5¹G7 | 30 | 50 | 80 | 110 | 130 | 180 | 200 |

| C6¹ | 3.5 | 4 | 6 | 5 | 6 | 6 | 6 |

| C71 | 42 | 60 | 90 | 115 | 142 | 190 | 220 |

| C8¹ | 90.5 | 111.5 | 152.5 | 191.5 | 235.5 | 303.5 | 378.5 |

| C9¹ | 8.75 | 13.5 | 10.75 | 13 | 15 | 20.75 | 53 |

| B1 h9 | 5 | 5 | 6 | 10 | 12 | 16 | 20 |

| H1 | 15 | 18 | 24.5 | 35 | 43 | 59 | 79.5 |

| Dimension | BABR042 | BABR060 | BABR090 | BABR115 | BABR142 | BABR180 | BABR220 |

| D1 | 50 | 70 | 100 | 130 | 165 | 215 | 250 |

| D2 | 3.4 | 5.5 | 6.6 | 9 | 11 | 13 | 17 |

| D3h6 | 13 | 16 | 22 | 32 | 40 | 55 | 75 |

| D4g6 | 35 | 50 | 80 | 110 | 130 | 160 | 180 |

| D5 | 22 | 45 | 65 | 95 | 75 | 95 | 115 |

| D6 | M4x0.7P | M5x0.8P | M8x1.25P | M12x1.75P | M16x2P | M20x2.5P | M20x2.5P |

| D7 | 56 | 80 | 116 | 152 | 185 | 240 | 292 |

| L1 | 42 | 60 | 90 | 115 | 142 | 180 | 220 |

| L2 | 26 | 37 | 48 | 65 | 97 | 105 | 138 |

| L3 | 5.5 | 7 | 10 | 12 | 15 | 20 | 30 |

| L4 | 1 | 1.5 | 1.5 | 2 | 3 | 3 | 3 |

| L5 | 16 | 25 | 32 | 40 | 63 | 70 | 90 |

| L6 | 2 | 2 | 3 | 5 | 5 | 6 | 7 |

| L7 | 4 | 6 | 8 | 10 | 12 | 15 | 20 |

| L8 | 139 | 163.5 | 206.5 | 285 | 365 | 431 | 521 |

| L9 | 4.5 | 4.8 | 7.2 | 10 | 12 | 15 | 15 |

| L10 | 100 | 12.5 | 19 | 28 | 36 | 42 | 42 |

| C11 | 46 | 46 | 70 | 100 | 130 | 165 | 215 |

| C2¹ | M4x0.7Px10 | M4x0.7Px10 | M5x0.8Px12 | M6x1Px12 | M8x1.25Px25 | M10x1.5Px28 | M12x1.75Px28 |

| C3¹G7 | ≤11/≤12 | ≤11/≤12 | ≤14/≤15.875/≤16 | ≤19/≤24 | ≤32 | ≤38 | ≤48 |

| C41 | 25 | 25 | 34 | 40 | 50 | 60 | 85 |

| C5¹G7 | 30 | 30 | 50 | 80 | 110 | 130 | 180 |

| C61 | 3.5 | 3.5 | 4 | 6 | 5 | 6 | 6 |

| C71 | 42 | 42 | 60 | 90 | 115 | 142 | 190 |

| C81 | 90.5 | 99.5 | 126.5 | 165 | 205 | 254.5 | 323.5 |

| C91 | 8.75 | 8.75 | 13.5 | 10.75 | 13 | 15 | 20.75 |

| B1h9 | 5 | 5 | 6 | 10 | 12 | 16 | 20 |

| H1 | 15 | 18 | 24.5 | 35 | 43 | 59 | 79.5 |